Role:

Design Engineer

Company:

AEG by Electrolux

Project:

Vacuum Drawer

Summary

A collaboration to design and develop an innovative, manufacturable vacuum drawer that seamlessly integrates into refrigerators. This solution was tailored to specific food types and optimized to streamline kitchen workflows, reducing food preservation steps. By applying advanced engineering principles, I ensured the design met manufacturability and durability requirements, balancing user needs with production feasibility.

Key Contributions:

Reduced preservation steps by 75%, improving kitchen workflow and usability.

Engineered a CAD model incorporating FMEA analysis and DFMA principles for optimized injection molding and manufacturability.

Debrief:

Design and develop a vacuum drawer that integrates into the fridge, prolonging the freshness of the food and creating a seamless experience by eliminating the transition between the vacuum and the fridge.

Research

User Journey

Competitors

Our competitor uses 0.8 atm vacuum in their fridges, but research shows this doesn't significantly reduce spoilage, and mixing incompatible produce can increase it.

Hitachi Vacuum Drawer

KPIs

Compatibility with AEG

single-door fridge

The product is limited by dimensions of 460 x 260 x 190 mm.

It plugs into the electrical system of the fridge.

Incorporating

vacuum technology

The pressure has a constant value of 0.6 atm.

Automatic sealing when the drawer is closed.

Releasing vacuum when the user opens the drawer.

Incorporating

Active humidity control

The drawer is kept at a constant humidity level of 80%.

Humidity control activates after the humidity exceeds 5% of the preset value.

Excess condensate is drained into the refrigerator's water tank.

Developments

Airtight Environment

An airtight environment is achieved through a sturdy shell and front face that interface through a perimetral gasket.

The user can access the drawer by using the handle, breaking the seal through a specialized valve.

The locking is achieved through the purpose-made mechanism

Air Control

Freshzone is powered by a Main Pump that utilizes a set of Valves and Sensors to control an airtight environment of 0.6 ATM of pressure.

The perfect conditions to keep food fresh, healthy and tasty for longer!

Humidity Control

Food kept in a sealed environment builds up humidity.

Freshzone regulates the environment by sensing when the air is becoming too moist. It opens the internal valve and runs the pump.

Let dry air from the fridge flow through the system, keeping a humidity level of 80%.

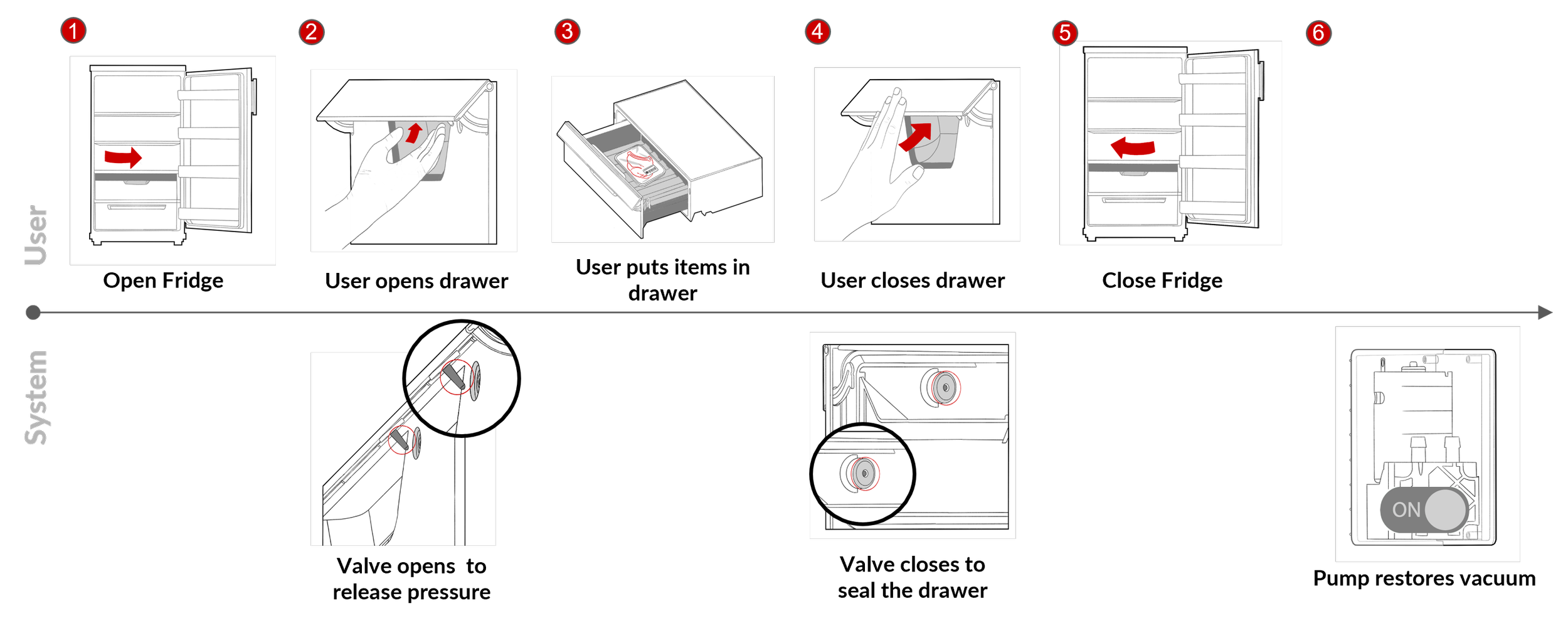

Freshzone Journey

User Journey

System Journey

Components & Materials

Exploded View

Material Selection

Architecture

Freshzone is connected to the fridge’s structure with reversible snap fits.

The wiring and the pump’s hose is run through the back of the fridge and into the foam where the pump is located.

The components plug in the power supply of the fridge without disturbing the existing architecture

Section View

Section Shown